Comparing Mechanical Properties of Bamboo: Guadua vs Moso

In 2010, the Larenstein University in The Netherlands performed an interesting study comparing mechanical properties of bamboo. Guadua and Moso, which are the best and most common bamboos for industrial processing, were used in this research report.

Of all the bamboo species in the world, about 88 species exhibit favorable properties for construction related purposes, like flooring, paneling, laminated lumber, etc. Especially tall and fast growing 'giant timber bamboo' is of interest because of their large dimensions and favorable yield.

The Chinese bamboo Phyllostachys edulis (Moso) is the commonly utilized bamboo species for industrial bamboo manufacturing in the world. China is the largest producer, and almost all products in the West are made from this species.

Moso Plantation

Guadua Plantation

Guadua angustifolia (Guadua) is hardly found in industrial manufactured products in the West (EU and USA), but since it is South America’s most important bamboo, and industrial activities are picking up, it is of interest to develop know-how on this species.

By testing these two bamboos, we will acquire more in-depth knowledge about the world’s 2 most important giant timber bamboo species.

Comparing Mechanical Properties of Bamboo

Mechanical properties of Guadua and Moso, were tested according to the KOMO-certified standard, which is the most commonly used standard for outdoor construction applications in The Netherlands. The tests are performed on single, non-laminated strips, in order to obtain data on the bamboo material in its natural condition.

In order to provide a point of reference, the test results were compared to 2 wood species. Norway spruce and dark red Meranti were chosen because they are commonly used in the Dutch market, and are often used for exterior applications.

Certification Institutes which are accredited by the government, check if a product meets the requirements, and award the KOMO-certificate if it does. In the Dutch construction sector it is common practice to use KOMO-certificates; one can hardly enter the market without having their product certified according to KOMO.

Macroscopic Features of Bamboo (Moso and Guadua)

Phyllostachys edulis or Moso has a reasonably fine grain, finer than Guadua due to its smaller vascular bundles. The nodal regions are small (due the small diaphragm), and do not result in a coarse surface after planing. Similar to Guadua, the concentration of the vascular bundles near the outside of the culm wall is high (Fig. 1), resulting in more ‘stripes’ on the tangential surface near the outside of the culm wall than on the inside (see difference between Fig. 2 and 3).

Fig.1 Moso - transverse surface of culm wall

Fig.2 Moso - tangential surface, outside of culm wall

Fig.3 Moso - tangential surface, inside of culm wall, with node

Guadua angustifolia or Guadua has a relatively coarse grain, due to its large vascular bundles (Fig. 4). These appear not to run strictly axial (wavy pattern), see Fig. 5. The nodal region is relatively large (Fig. 6), due to the large thickness of the diaphragm, and results in a coarse surface after planning. Just as for Moso, note the difference between the outside and inside of the culm wall.

Fig.4 Guadua - transverse surface of culm wall

Fig.5 Guadua - tangential surface, outside of culm wall

Fig.6 Guadua - tangential surface, inside of culm wall, with node

Microscopic Features of Bamboo (Moso and Guadua)

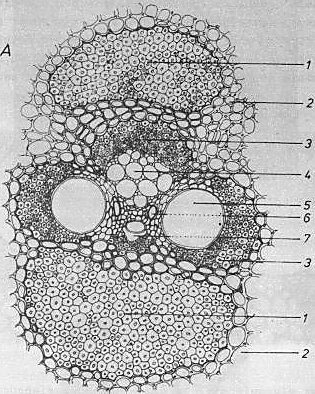

The ground tissue of a bamboo culm consists of parenchyma cells, with embedded vascular bundles composed off metaxylem vessels, sieve tubes with companion cells, and fibers. Bamboo tissue is approximately composed of 52% parenchyma, 40% fibers (sclerenchyma sheaths and separate fiber strands) and 8% conducting tissue (tubes).

The concentration of the vascular bundles on the outside of the culm wall is high, and low on the inside (see Fig. 1 and 4 above). Therefore, the percentage of fibers (sclerenchyma or separate fiber strands) decreases towards the inside of the culm wall.

Furthermore, the numerous vascular bundles near the outside of the culm wall are small in diameter, where the ones in the center and near the inside of the culm wall have a large diameter. Due to the presence of fibers, vascular bundles determine the strength of a culm. The cells are all strictly axially orientated within an internode, except the vascular bundles seize to run straight in a node where some of them bow off into the horizontal diaphragm.

Fig.7 Composition of a bamboo vascular bundle

The microscopic features of a vascular bundle are described in Fig. 7, note that these features are not present in every bamboo species.

Details of vascular bundle:

Fiber strand

Parenchyma

Sclerenchyma sheaths

Phloem (sieve tubes with companion cells)

Metaxylem (vessel)

Smaller metaxylem element

Intra-cellular pathway, strengthened by the remainder of the original tube-element (protoxylem)

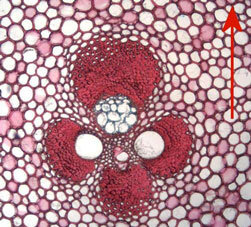

Figures 8 and 9 are meant to characterize the micro structure of both bamboo species. Both bamboos have microscopic features which are quite different compared to wood. Only features of the center of the culm-wall were photographed, because this region exhibits most characteristic features.

Fig.8 Moso vascular bundle (40x).

Transversal surface - center of culm wall.

Arrow points towards outside of culm wall.

Fig.9 Guadua vascular bundle (40x).

Transversal surface - center of culm wall.

Arrow points towards outside of culm wall.

It proved to be difficult to cut a coupe in transverse direction for Guadua, what most likely is caused by the toughness of the vascular bundles which are large in diameter; sclerenchyma cells have an extremely thick cell wall.

Moso and Guadua both have in common that phloem and xylem (conducting tissue at the heart of a vascular bundle) are surrounded by sclerenchyma sheaths; no separate fiber strands are present. Moso has four sclerenchyma sheets which are fairly equal in size. Thylosis is noticeable inside the intracellular pathway. Guadua also has four sclerenchyma sheets, of which two (left and right) are of equal size. The sclerenchyma sheath which surrounds the intra-cellular pathway is much smaller, and the sheath that surrounds the phloem is remarkably thick. No thylosis was observed.

Note: There is a high variation in micro-structure of the vascular bundles between the lower and upper parts of the culm.

Starch Content of Bamboo

Fig.10 Parenchyma cells (ground tissue) filled with starch granulae in Phyllostachys viridiglaucescens.

Bamboo tissue contains several organic and inorganic inclusions (extractives), which are deposited within the cell walls as an encrusting material.

One of the inclusions which is often discussed with regard to the durability of bamboo is the starch content. The starch content of the parenchyma cells influences to a larger extent the susceptibility to attack by fungi, especially blue stain fungi, and beetles. Starch grains occur abundantly in the parenchyma cells that form the ground tissue (see Fig. 10), and in parenchyma in the vascular bundles. Even fibers may contain starch.

Starch serves as an energy resource for the production of new shoots. The amount is influenced by several factors:

Season: Mature bamboo culms have a higher starch content during dry season for new shoot growth in rainy season.

Age: Virtually no starch is present during the first year of growth, and gradually increases when the culm becomes older.

Culm part: The lower part of the culm has a higher durability as middle and top parts due to the lower concentration of starch in the bottom parts, and the inner part of the culm wall has a lower durability than the outer part, which is attributed to the higher content of nutritious parenchyma in the inner part.

Species: There is a considerable difference in starch content among different bamboo species.

Density of Bamboo (Moso and Guadua)

The density of both bamboos is shown in the chart below. The density was measured for Moso at a moisture content of 10.3%, and for Guadua 12.6%. Literature values of Norway spruce and dark red Meranti were added for a comparison.

Density [kg/m³]

Both bamboo species have quite similar densities; Guadua is denser than Moso, what most likely is caused by its higher moisture content. Although nodes have a higher density than internodes in both species, the difference is not significant. The density of both bamboos seems less than dark red Meranti (note the higher MC), but higher than Norway spruce.

The 5%-quantile values of the average density (nodes and internodes together) are shown in the chart below.

Density [kg/m³]

These values are calculated in order to compare the properties of bamboo to strength classes for timber (together with the MOE and MOR).

Conclusion: The density of both bamboos is of a similar order of magnitude as timber species commonly used for exterior joinery applications. The EMC of both bamboo species is of a similar order as wood. In a climate of 65% RH and 20°C, Moso leveled out at an EMC of 10.3%, Guadua at 12.6%.

Hardness of Bamboo (Moso and Guadua)

The test results of the Janka hardness test are shown in the graph below. The hardness was measured for both internode and nodes, and for the outside and inside of the culm wall. For a comparison, literature values for Norway spruce and dark red meranti are given.

Janka [N]

For both species, the outside of the culm wall proved to be harder than the inside of the culm-wall. A similar difference is observed for node and internode sections. The hardness of Moso is about twice as high as the hardness of Guadua, and can be compared to the hardness of European Oak (6280 N). Whereas Moso is harder than dark read Meranti as well Norway spruce, Guadua is less hard than the Meranti but harder than Norway spruce.

Conclusion: The hardness of Moso (comparable to European Oak) makes it a suitable material for applications which need to be resistant against indentions (door frames for example), Guadua seems not to be a first choice material for applications which face a high risk of indentions.

Strength of Bamboo (Moso and Guadua)

The results of the 4-point bending test are shown in the graphs below. The modulus of elasticity (MOE) and modulus of rupture (MOR - bending strength) is shown in the figures below.

The MOE and MOR were measured for both internode and nodes, and with the outside and inside of the culm wall alternately placed upwards (loaded in compression). For a comparison, literature values for Norway spruce and dark red Meranti are given.

MOE [N/mm²]

Guadua bamboo has the highest modulus of elasticity (MOE), significantly higher than the MOE of Moso, and is even more stiff than dark red Meranti as well as Norway spruce. The sections with a node are less stiff as node-less sections, the difference in positioning of the in- and outer culm wall seems of little influence on Guadua’s MOE. Moso has a relatively low MOE compared to Guadua, and is less stiff than both dark red Meranti and Norway spruce. Contrary to Guadua, sections with a node have a higher MOE than those without. There is a small difference in MOE depending on the positioning of the in- and outside of the culm wall; the MOE is a bit higher when Moso’s outer culm wall faces upwards (loaded in compression).

MOR [N/mm²]

Both Moso and Guadua have a similar bending strength (MOR), which equals the MOR of dark red Meranti and is higher than Norway spruce. Guadua has a higher bending strength when the outside of the culm-wall is placed up (loaded in compression), and sections with a node are able to stand less force as node-less sections. Moso has a fairly homogeneous bending strength, there is no large difference between a node and an internode, as well for the influence of positioning of the in- and outside of the culm-wall on the MOR.

When the strength properties of both species are compared to strength classes for timber (using the average MOE and the 5%-quantile values for the MOR and density), Moso would belong in strength class C16, and Guadua in strength class C35.

Conclusion: Both bamboos have a bending strength (MOR) that is superior to many timber species which are commonly used in the Dutch construction sector. However, Moso has a low stiffness, which does not make it a very suitable material for load bearing applications (strength class C16).

Guadua is stiffer than Moso, even more stiff than dark red Meranti and Norway spruce, which makes it an excellent species for load bearing applications (strength class C35). Guadua is likely to stay stiff enough in order to not deform and cause a construction to loose its shape. Moso has a relative low MOE in relation to its MOR, which will cause a laminated beam which is used in a load bearing construction to bend faster than an often used timber such as Norway spruce would do.

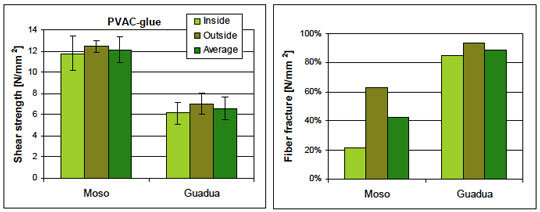

Gluability of Bamboo (Moso and Guadua)

The results of the gluability are shown in the charts below. The tensile shear strength of the bond between the glue and the bamboo surface are shown in the charts on the left. The percentages of fiber fracture are shown in the charts on the right.

PU-glue, tensile shear strength and fiber fracture

The PU-glue bond did not perform as expected. It is known to have tensile shear strength of at least 10 N/mm² on wood. Instead, the glue bond fully fractured at relatively low values, without significant fiber fracture. Interestingly, the tensile shear strength is higher for Moso than for Guadua, indicating the glue was able to form a better bond with the surface of Moso.

PVAC glue, tensile shear strength and fiber fracture

The PVAC-glue bond was able to withstand over 12 N/mm² for Moso, with only 38% fiber fracture. Yet, the PVAC-glue bond with Guadua only reached a little over 6 N/mm², with 85% fiber fracture.

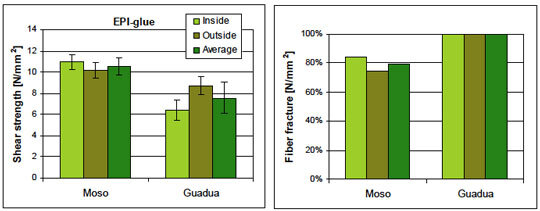

EPI-glue, tensile shear strength and fiber fracture

The EPI-glue bond withstood over 10 N/mm² for Moso, with 78% fiber fracture. The same glue bond with Guadua only reached a little over 7 N/mm², with 100% fiber fracture.

Conclusion: Although the gluability has not been tested according to the BGS (T-joints and accelerated weathering), it can be concluded that the bamboos can be glued very well with commonly used glues, namely EPI-glue and an PVAC-glue. The used PU-glue was not suitable for gluing either bamboo, what most likely is caused by its chemical composition. Therefore, bamboo is not suitable for all glues.

Moso can be glued well with a PVAC and EPI-glue, considering they both were able to withstand a tensile shear strength of more than 10 N/mm² (required performance for a glue to get certified).

Guadua can be glued with both glues, indicated by the high percentages fiber fracture at the moment of breaking. However, the maximum tensile shear strength between the glue bond and the bamboo surface, was less than for Moso. This is most likely caused by a different micro-structural organization of cell types, for it appeared to be mostly the soft parenchyma tissue which fractured (both for the inside and out side of the culm wall). Nonetheless, this is not a bottleneck for producing laminated bamboo for use in a load bearing application because the glue bond has a more than sufficient strength.

Treatability of Bamboo (Moso and Guadua)

Bamboo in exterior applications has to withstand the influences of weathering, which requires a suitable durability. At the start of this project it was known that bamboo’s natural durability is rather low. To research the possibilities for improving the durability, and to obtain knowledge on the materials behavior, bamboo was tested for the possibility of impregnation (curing). This was done by means of pressure treatment (the ‘full cell process’) with a copper solution in water.

In order to research the pathways through which the solution would be impregnated into the material, the ends (cross cut) of the specimens were sealed with an epoxy resin in various ways; the first two tests were performed with one closed end and one open, with the difference that one series had a node just behind the open end. The third test was performed on specimens with both ends sealed.

Before the treatment, the specimens were conditioned in a climate of 65% RH and 20 °C. This means the material was relatively dry, where in practice bamboo is often impregnated when the culm is still fresh (Boucherie process; sap replacement). Literature mentions the increased difficulty of impregnation once bamboo is dry, due to the blockage of certain pathways. The amount of copper solution which was able to ingress into the material is shown in the graph below.

Uptake [% w/w]

The amount of copper solution which was able to ingress into the material is significantly less for Moso than for Guadua. A statistical probability test indicated that there is no significant difference in treatability between the specimens with an open end, and with a node just behind the open end. In other words, a node seems not to effect treatability significantly.

Specimens with an open end were impregnated with a reasonable amount of solution, this was not the case for specimens with both ends sealed. For Moso, the amount of solution which was able to ingress into the material, is significantly less in the case of two ends sealed compared to only one end sealed. This difference is also noticeable for Guadua, however it is not significant.

Compared to Norway spruce and Scots pine, the amount of solution which is able to ingress into the material seems to be at least equal.

Conclusion: Both Moso and Guadua are treatable with a copper-solution by impregnating it, even when the material is dry. Because of the higher uptake of solution under pressure treatment, Guadua is more suitable for impregnation than Moso.

Compared to the average treatability (water retention) of Norway spruce and Scots pine, both bamboo species seem at least equally well treatable. However, the copper-solution chooses the vascular bundles as primary pathway if the cross-section sides are open (what will be the case in practice), hereby leaving a part of the parenchyma tissue untreated. This causes the copper (or other protective agent) not to be dispersed evenly throughout the material, leaving certain parts (parenchyma cells) susceptible to attack of degrading organisms. Therefore, treating bamboo by means of impregnation might not be the best choice for the highest protection against degrading organisms.

Final Conclusion: Moso vs Guadua

According to the Dutch bamboo sector, laminated bamboo (in its natural condition) is not suitable for outdoor applications, and has limited perspective. Bamboo composite (strand woven bamboo) on the other hand, is regarded to have a very promising perspective for exterior applications.

The results were that, although not all requirements were researched, the material properties that were tested indicated that both bamboos meet the requirements, and do not deviate much from commonly used timber species.

Source: Valentijn de Vos (2010)