Bamboo Joints and Joinery Techniques

Basic Principles and Techniques

How to join bamboo and what are the best bamboo joints? Well first of, it is important to know a few basics principles about joining bamboo before discussing the different joinery techniques. So here goes...

Do not use green, fresh cut bamboo. Bamboo has to be completely dry before using it in construction (preferable air dried). During the drying process the bamboo diameter shrinks, so when bamboo is used in joinery this will result in lose and weak joints after a few weeks.

Do not use bamboo when it is less then 3 years of age. Only use mature bamboo of 4-6 years.

Do not use bamboo infected by insects (powder beetle for example). Bamboo has to be properly cured with a boron mix immediately after harvesting.

Do not use bamboo that has flourished. Rest assured bamboo only flourishes once in a lifetime (60-120 years).

Do not use bamboo poles with profound vertical cracks.

Use appropriate cuts and joints when building with bamboo.

Use bamboo with the right diameter and wall thickness for your project.

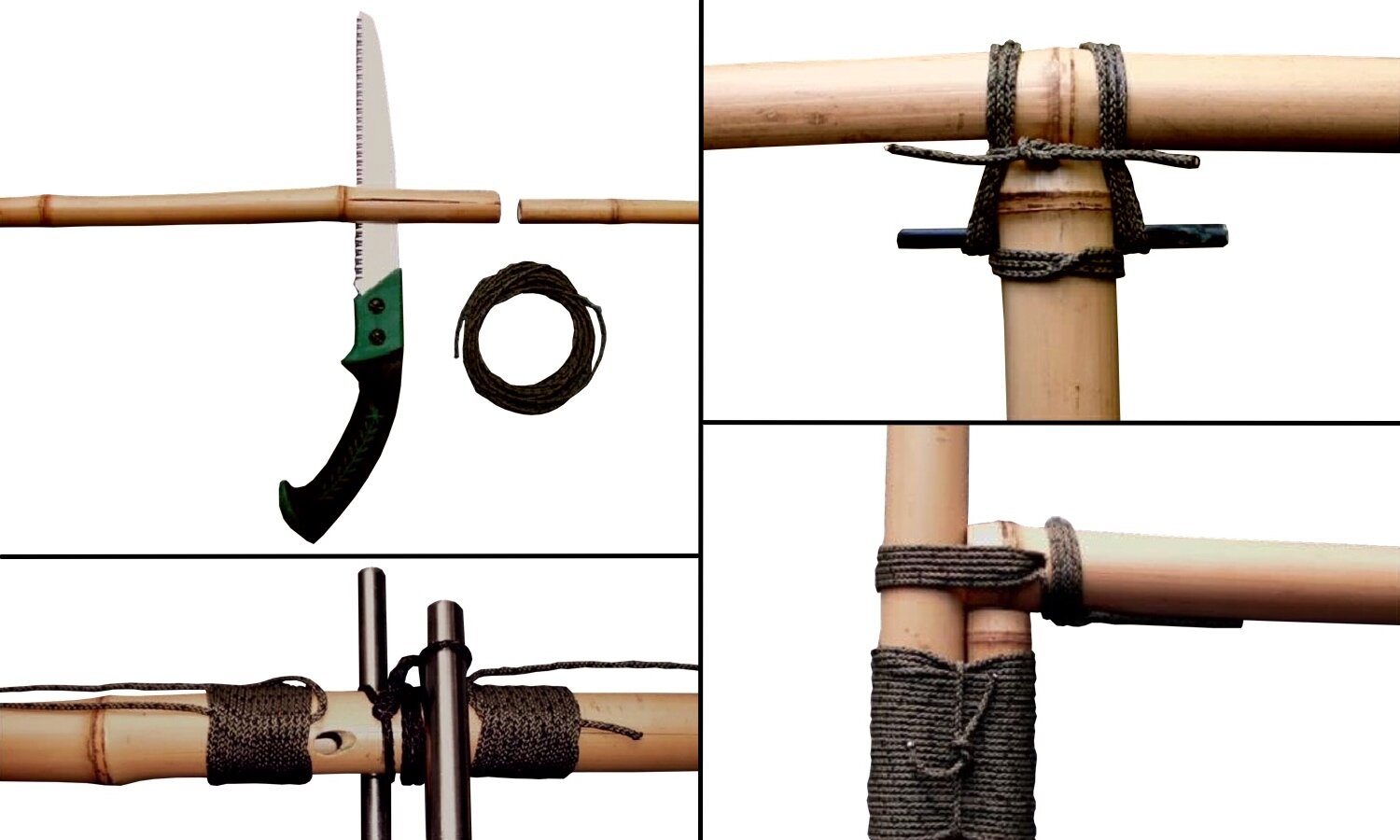

Do not use conventional wood nails in bamboo joinery, they will cause the bamboo to split. Instead use nylon, steel or vegetal cord of the appropriate diameter.

When using bamboo as a column make sure that the lower part connecting with the surface ends with a node. If not the bamboo will splinter when struck (for example to position the column).

When connecting bamboo poles with bolts, make sure to bolt them together in between 2 nodes, otherwise the bamboo may crush. More about utilizing the nodes below...

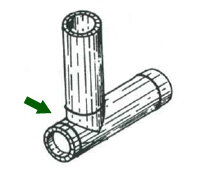

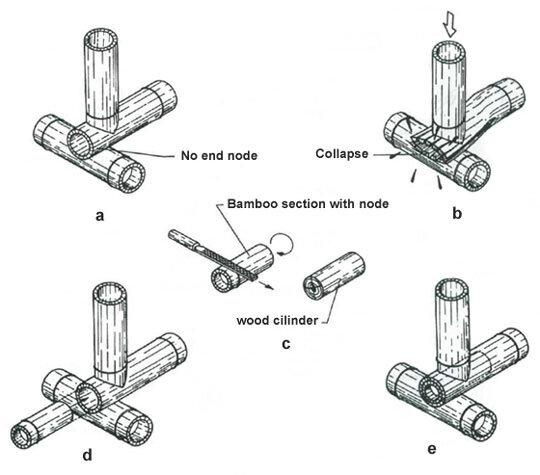

Bamboo Has Nodes, Use Them!

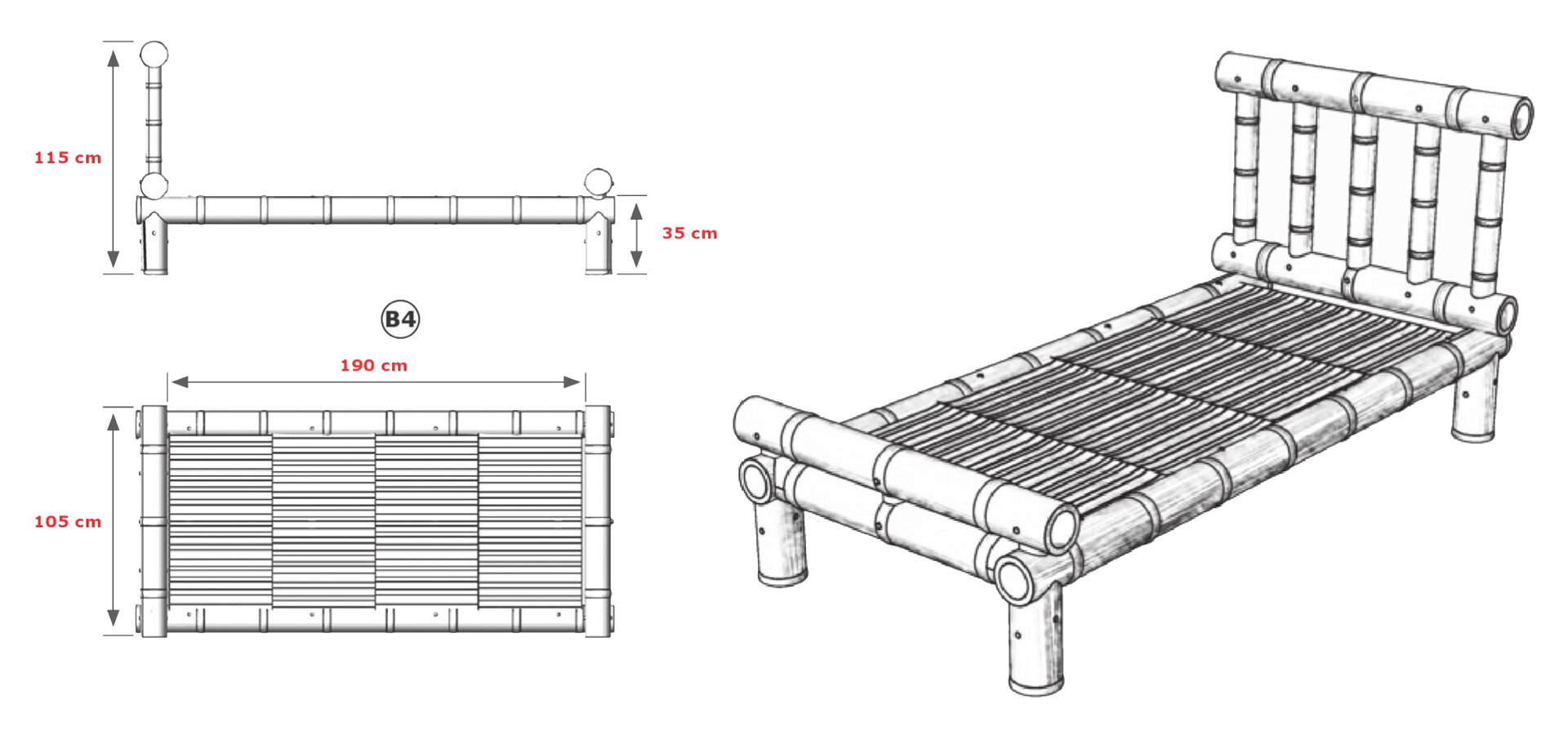

In construction, using bamboo nodes is very important. Bamboo columns or beams need to have a node at both ends (or as close as possible towards the ends), if not the pressure of a structure on the joint may crush the bamboo.

Often it isn't possible to find bamboo of the required length with both end nodes in place. When this occurs you should insert a wooden cylinder of the appropriate diameter or a fitting piece of bamboo with a node.

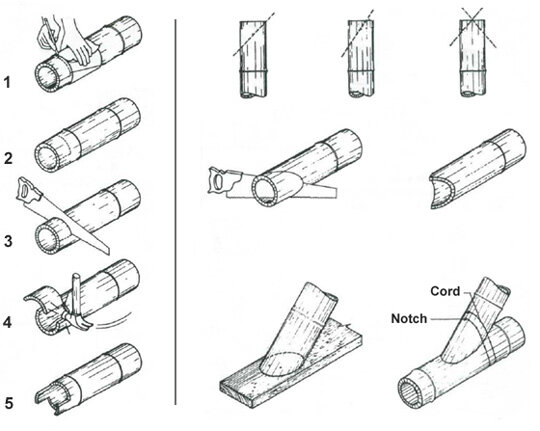

Bamboo Cuts

These are the most common cuts to use when making bamboo joints:

one ear / two ear / beveled / flute mouth / fish mouth

As you can see in the illustration below, making basic cuts in bamboo doesn't require expensive or heavy power tools, just a few traditional hand tools will work fine.

Bamboo Joinery Techniques

Making good and aesthetically pleasing bamboo joints is rather complicated because bamboo is hollow, tapered, has nodes at varying distances, and it is not perfectly circular. It is important to keep all these constraints in mind when designing a bamboo joint.

Although traditions, local practices and publications give some information on bamboo joinery, this information is far from complete as essential data is missing in most cases. Many traditional joinery techniques suffer from weakness or deformation, where the strength of the bamboo culm itself is lost.

Before bamboo gets widely adopted in modern architecture (and becomes affordable for all to use), the problem with bamboo joints and universal joining systems has to be solved. After all, timber, steel, and more recently prefabricated concrete, only became proper building materials for the same reasons. How many cumbersome solutions for joints have one seen, before these materials became a standard in construction?

Only if the problem with bamboo joinery can be satisfactorily addressed, and simplified, we can expect to see much more bamboo in Western buildings, bridges and furniture.

Below you'll find some examples and illustrations of traditional bamboo joinery techniques.

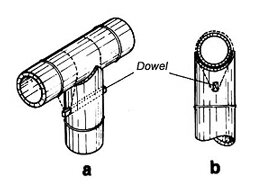

Joining horizontal with vertical elements

1. Joint with one or two ears. Is used to join bamboo rafters, logs or lumber.

2. Flap joint. Is used when there is no lashing wire available. The flap can be secured with bamboo strips.

3. Fish mouth joint.

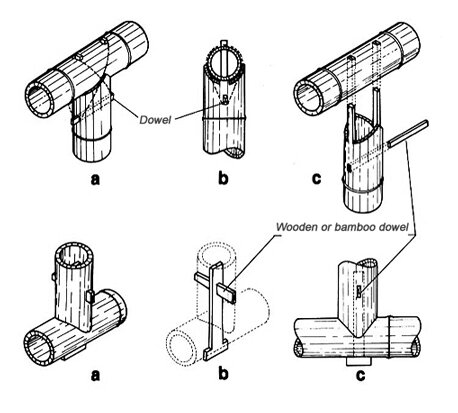

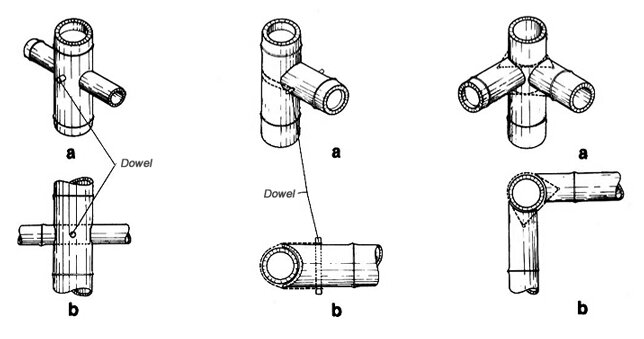

Use of dowels and anchors in bamboo joinery

1. Joining bamboo with dowels and lashing. The peg should be placed in the column parallel to the rafter.

2. Fish mouth joint with pegs.

3. Bamboo joint with wooden anchor. Is also used inverted.

4. Bamboo joint with metal anchor. This technique Is used in various positions.

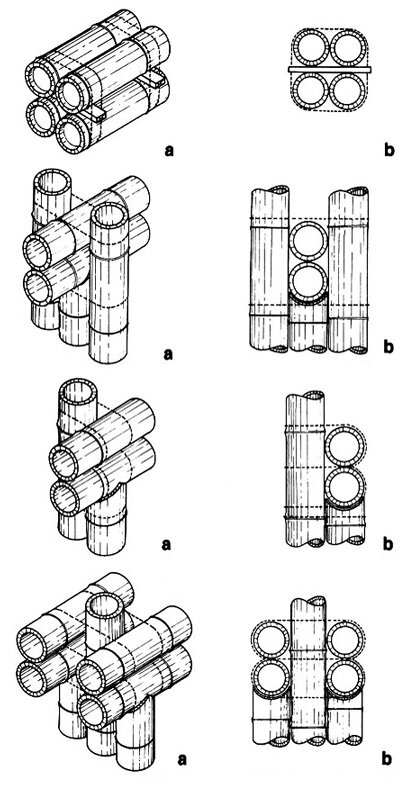

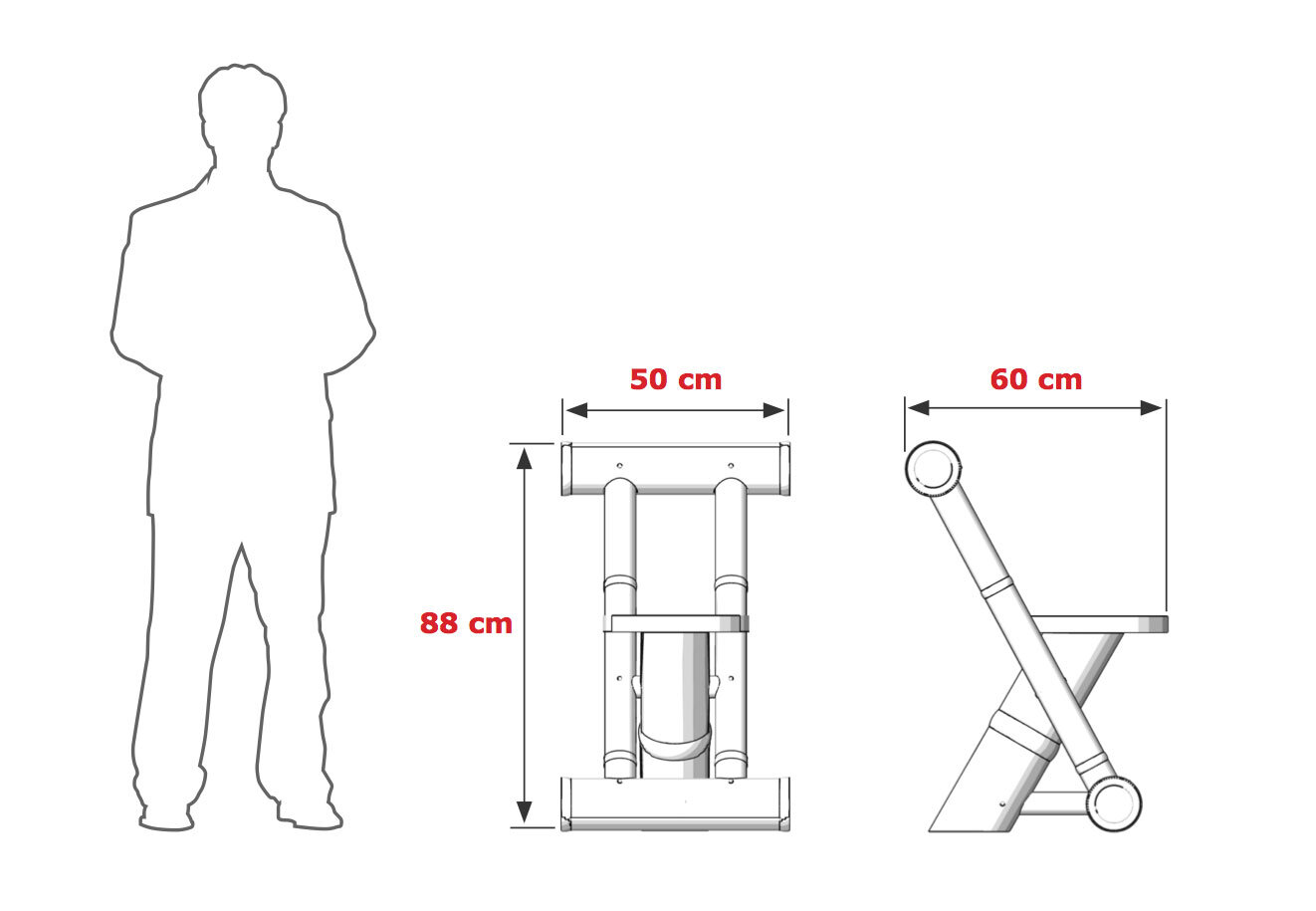

Double and quadruple bamboo rafter support

1. Beams formed by 4 or 6 members. The top row is separated from the bottom with wooden or bamboo slats so that the upper bamboos do not slide over the lower.

2. Central double rafter. It has a wide range of applications in the construction of bridges and structures for rural facilities.

3. Lateral double rafter. Each of the rafters is secured independently at the side support and each other. It is often used in the construction of bridges and structures for rural facilities.

4. Lateral double rafters. Is often used as a central support for bridge structures or sheds.

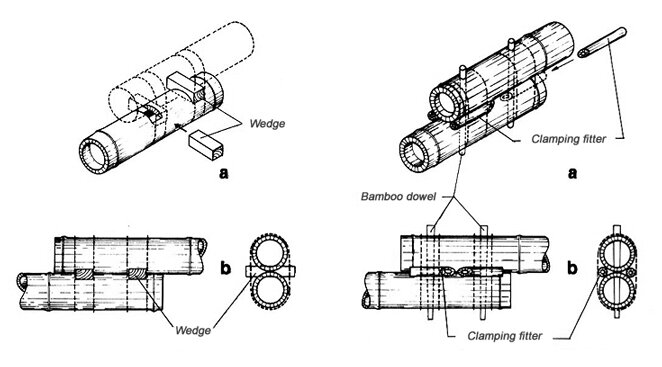

Joining and fixation of bamboo poles

1. Joint with double wooden wedge.

2. Joint with dowels and clamping fitters.

3. Cross joint with dowel.

4. Lateral joint with dowel.

5. Corner joint.

Splicing bamboo poles

1. Top splicing.

2. Bevel splicing.

3. Ray splicing

4. Half bamboo splicing.

5. Splicing with internal union.

6. Splicing with external union.

7. Telescope splicing.

Source: Oscar Hidalgo Lopez, Manual de construcción con bambu.

This video from the Technology Institute in Costa Rica shows a basic technique in bamboo construction: the bamboo fish mouth joint. Notice the backslash of the drill in the beginning of the video. Guadua bamboo is a thick walled timber species, so be careful when you try this at home!