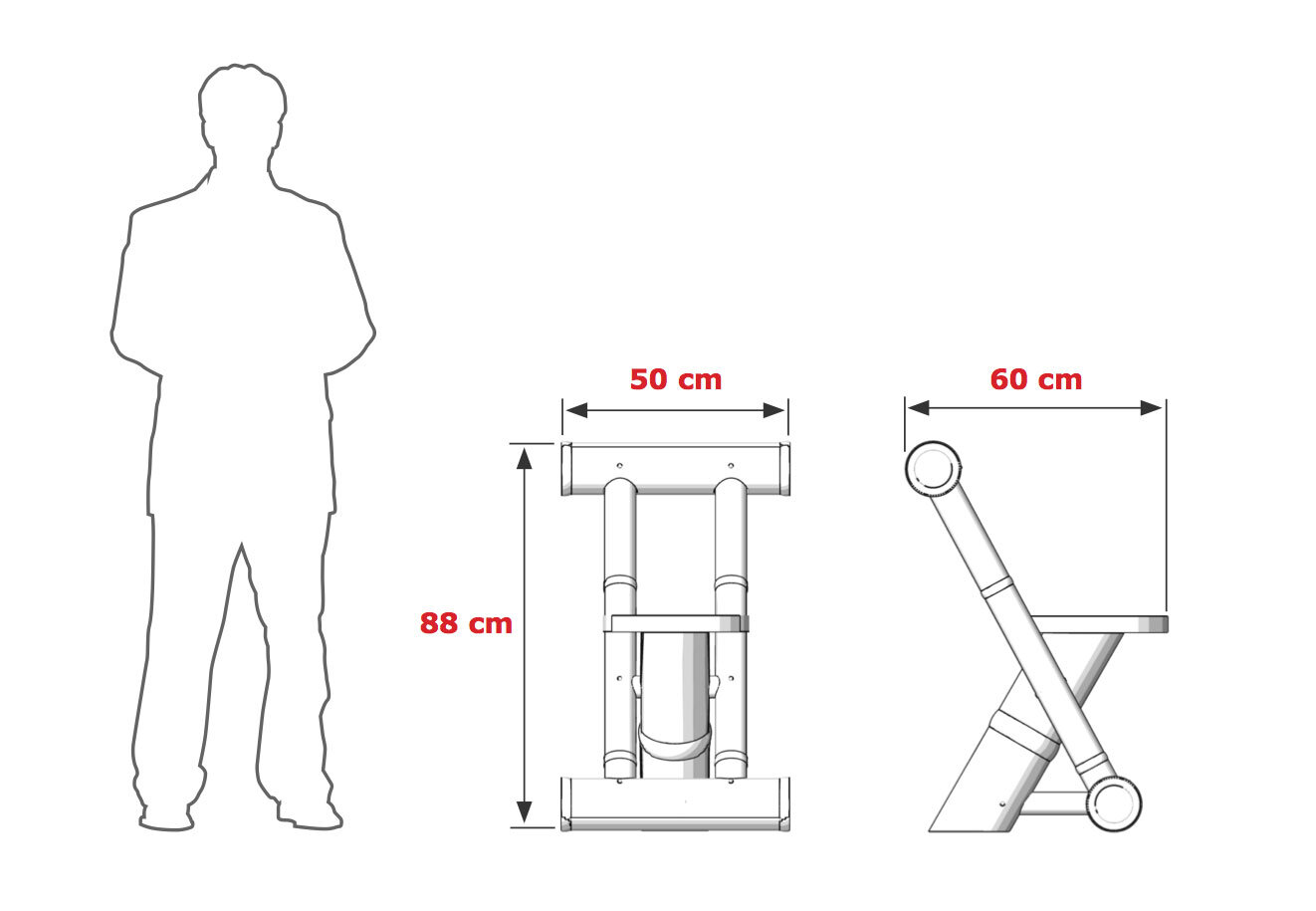

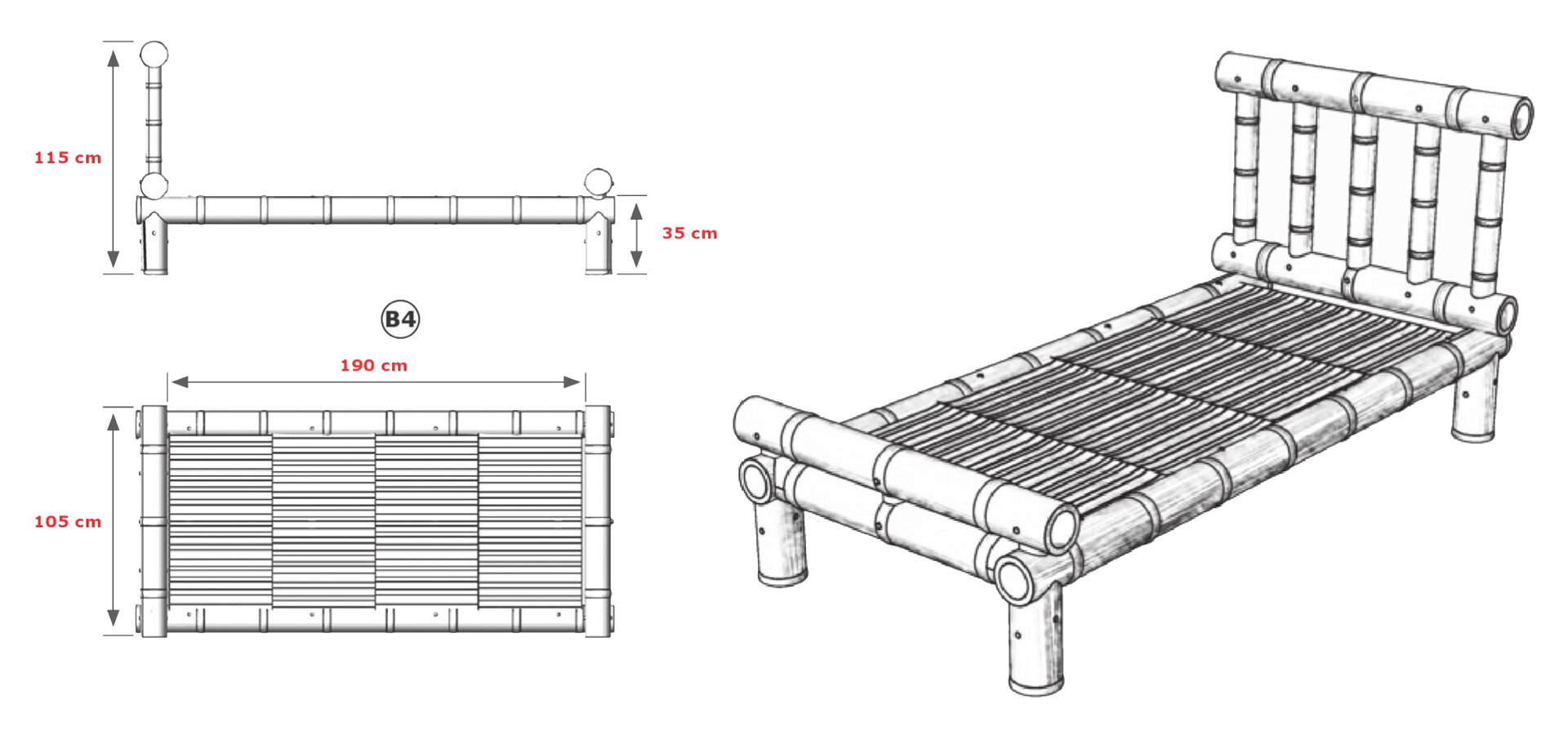

Bamboo Lashing Manual

Bamboo is one of the most useful plants as it can be used to make houses, traps, cages, furniture, tools, weapons, bridges, rafts, towers, fences, water wheels, irrigation pipes, and thousands of other items. The challenge however, is learning how to connect those bamboo canes.

Bamboo poles can be tied together using any of the traditional lashing knots, such as the square lashing, round lashing, diagonal lashing, shear lashing, tripod lashing, floor lashing, or ladder lashing. But, there are also more advanced techniques for joining or lashing bamboo sticks together by using pegs or braces of which we will show some examples below:

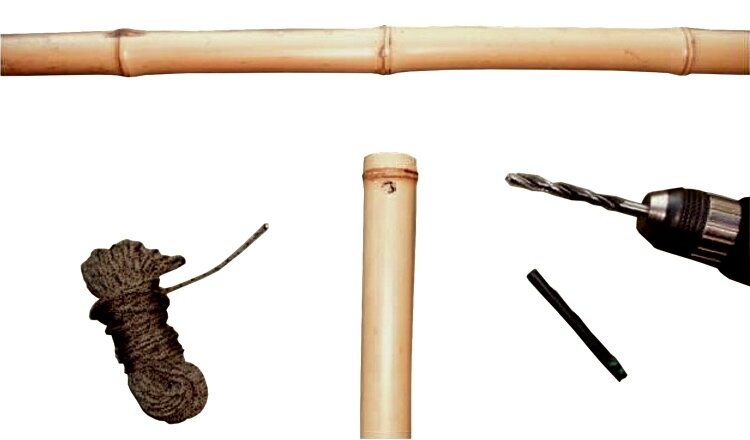

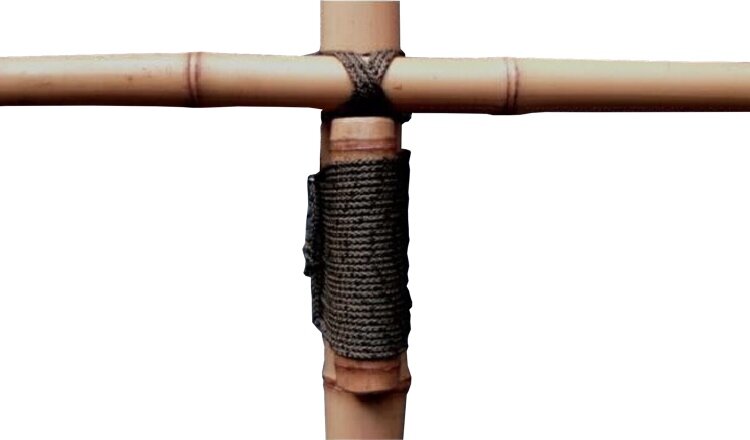

Drilled Lashing Joint

1. One of the simplest bamboo joints is the drilled lashing. An upright pole is cut above a node, and a hole is drilled all the way through the pole, just below the node. A cross-pole is then secured to the upright by a lashing through the hole. For maximum strength, a node of the cross-pole should be positioned on the upright. Lashing on both sides of the cross-pole node prevents the bamboo poles from shifting.

2. A piece of wire bent in half (or an improvised wooden needle) makes threading cordage through the drilled hole easier, especially the last pass or two after the hole is already packed with several strands of cordage.

3. Here is the completed joint showing how bamboo lashings are made on both sides of the cross-pole node. The lashing is finished with a clove hitch around the upright and a square knot. Tying lashings around any drilled hole is a good way to strengthen the joint and helps prevent bamboo poles from splitting.

4. The drilled joint can also be used to connect the end of a cross-pole to an upright, as shown above. For this application, the lashings should be tied above a node on the upright. Downward pressure on the cross-pole will simply tighten the bamboo lashings further as they encounter the larger diameter of the node. This is one of the most basic principles used in bamboo construction; having the nodes work for you to prevent slippage.

5. Drilled bamboo lashings can be used to connect more than one cross-pole to an upright, which is a good way to make bamboo frameworks.

6. Using the drilled lashing, two cross-poles can be connected to an upright at right angles to form a corner joint.

7. Drilled lashings have been used to connect three cross-poles to an upright as in this example.

8. In this example, drilled lashings have been used to connect four cross-poles to an upright. Once the bamboo joint has been formed and tied in place, extra lashings can be added for reinforcement if desired.

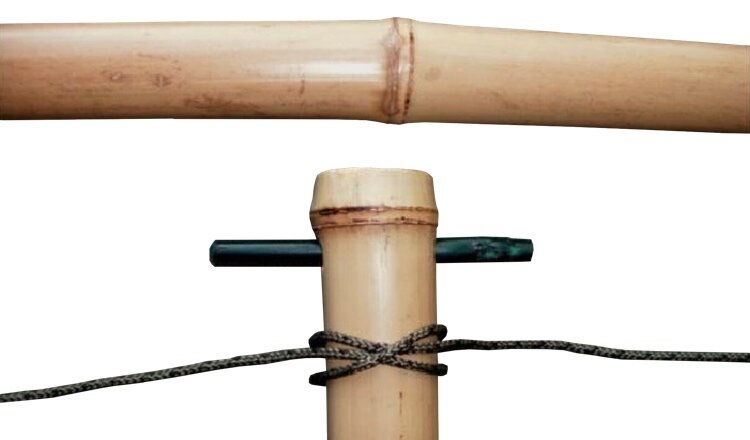

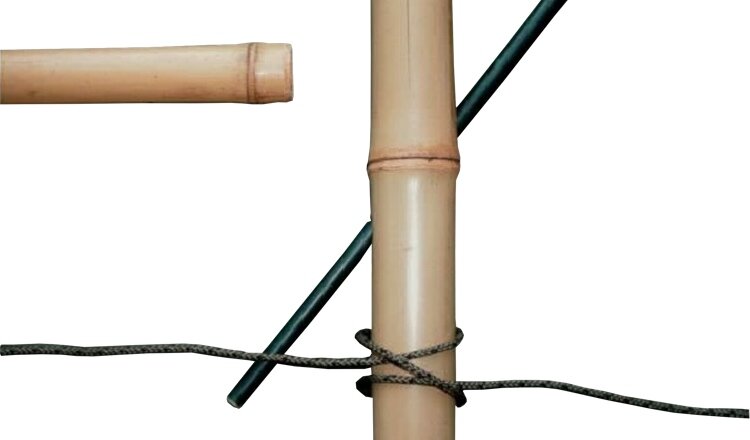

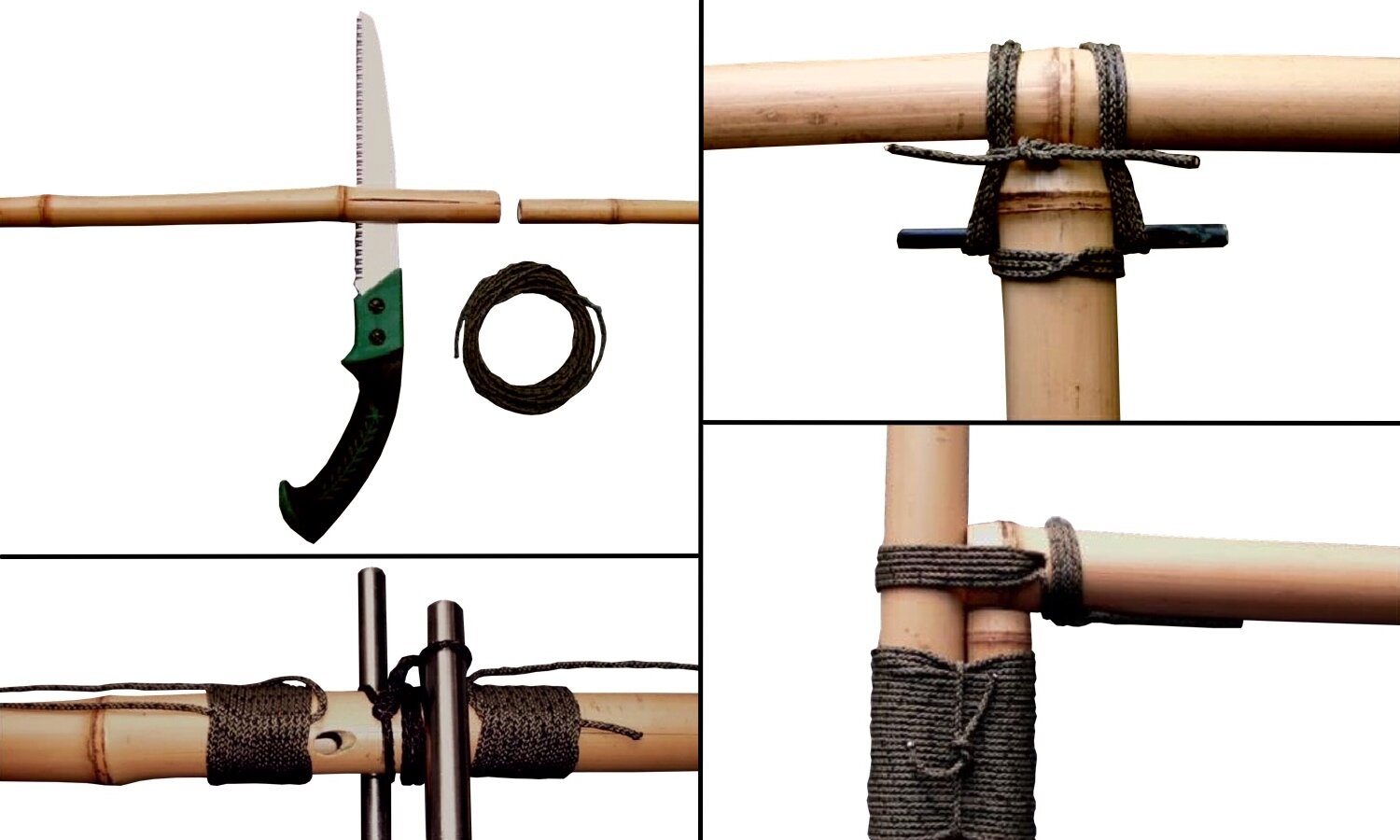

Pegged Lashing Joint

1. A variation of the drilled lashing is the pegged lashing where a bamboo peg is inserted into the drilled hole and then the lashings are tied around the peg instead of being threaded through the hole. The strength of this joint is limited by the strength of the peg, so use a bamboo peg that has thick walls, or a hardwood peg.

2. Start the pegged lashing by tying a clove hitch on the upright below the peg.

3. Lash the bamboo poles together, then add one or more frapping (tightening) turns around the lashings and finish with a square knot. The lashings could also be criss-crossed over the cross-pole if you prefer.

4. Another way to make pegged bamboo lashings is by aligning the peg at right angles to the cross-pole as shown here.

Slant-Peg Lashing Joint

1. This bamboo joint is a slant-peg lashing. A hole is drilled above a node on an upright bamboo pole, so that it passes through the node and comes out below the node on the other side. The exact angle can be adjusted a bit as desired.

2. A long peg is inserted through the slanted hole and will be used as the support for a cross-pole.

3. The lashing is made by starting with a clove hitch.

4. This bamboo lashing was made with a single cord. Separate lashings between the two main bamboo poles and around each point where the peg passes through the upright could be made instead and would probably look neater.

Pegged Socket Joint

1. This joint is a pegged socket joint. A hole is drilled into an upright bamboo pole at the right size to fit a smaller cross-pole.

2. The cross-pole is then fitted snugly into the socket until it touches the back wall of the upright bamboo pole.

3. A hole is drilled through both pieces so that a peg can be inserted to pin the joint together. This joint is often used to make bamboo ladders, using two larger uprights, and smaller cross-poles for the rungs. Maximum strength is obtained by locating the cross-poles just above the nodes on the upright poles. The pegs can be cut off flush, or left protruding to make disassembly easier.

4. Lashings should be added to these bamboo joints to help prevent splitting under heavy loads.

Key Joint

1. This joint is called a Key Joint. An upright bamboo pole is drilled to allow a key piece to be installed. The key supports a cross-pole, and the key and cross-pole are secured together with a pin.

2. The hole in the cross-pole is made just large enough for the body of the key to fit inside but not large enough for the node at the end of the key to pass through.

3. The key piece is installed in the hole of the upright bamboo pole so that the node jams against the side. The end of the cross-pole is drilled out so that the key piece can fit inside.

4. The cross-pole is fitted onto the key piece, until it contacts the upright.

5. The cross-pole and key piece are drilled so that they can be pinned together.

6. Finally, the pin is used to secure the finished bamboo joint, as shown here. Lashings can be added, if desired. Note: A large key piece was used for this tutorial, but a smaller key would weaken the upright less.

Lashed Cross-Pole Support Joint

1. This joint is a lashed cross-pole support. A section of bamboo is lashed to an upright, as shown here. Longer supports can also be used, and these should be lashed at the top, bottom, and center.

2. The cross-pole is then lashed to the upright above the support.

3. The lashed cross-pole support can also be combined with the drilled lashing for use when the nodes are not in a convenient location. Just vary the length of the support to reach the nearest node below the cross-pole.

Diagonal Braces

1. Diagonal braces can be added to almost any bamboo joint to provide extra stability. Note how the support is positioned so that the ends connect at nodes for maximum structural strength. Lashings can also be added as needed.

2. Two diagonal braces can also be used instead of one. Multiple holes may weaken the bamboo upright if drilled at the same point, so braces should be staggered or even connected at different nodes on the upright.

3. Lashings above and below braces that do not end at nodes are critical to guard against splitting.

4. Diagonal braces can be added to any of the bamboo joints that form right angles. The ends of the diagonal braces can be pinned in place or securely wrapped and lashed in place if desired.

Clamped Socket Joints

Bamboo poles of different sizes can be connected by inserting a smaller pole into a larger pole. The end of the larger pole must be lashed first to prevent splitting. Socket joints like this are used for making long fishing poles or spears and for flagpoles. Variations include pinning the smaller pole in place before lashing, cutting slots in the end of the larger pole so that the ends clamp down on the smaller pole as the lashings are tightened, and just using a tight friction fit to hold the poles together. The friction fit is good for uses where the object will be disassembled, and for holding a short fore-shaft for a spear-head or harpoon.

Bamboo water pipes are made by knocking out all of the node walls with a pipe that fits inside the poles, then fitting the small end of one pole into the large end of the next pole.

Two poles can be connected using a smaller internal pole for a splice. The inner pole can be left visible or the two larger poles can be touching with the inner pole concealed inside. The ends can be pinned or clamped.

1. To make a clamped joint, saw or split the larger bamboo pole down to the first node twice, making four sections. Note: Adding a lashing to the pole on the other side of the first node will keep the splits from going too far.

2. Enough material must be removed at the saw cuts (or splits) to let the sections clamp onto the inner bamboo pole.

3. The smaller bamboo pole is inserted into the larger pole until it reaches the node section.

4. Verify that the sections have enough material removed from the gaps to allow them to clamp onto the inner pole securely before adding any lashings by squeezing the ends by hand and removing more material if necessary.

5. Start the bamboo lashing at the node end as shown, wrapping the cordage over a long loop of the cord.

6. After making several tight turns, pull on the end of the loop to tighten up the first turn of cord.

7. Continue adding turns keeping the cordage neat and tight and then put the end of the cord into the loop.

8. Pull on the beginning of the cord to draw the loop tight against the lashing turns.

9. Now keep pulling and the loop will be drawn under the bamboo lashings, taking the end of the cord with it.

10. Finish the lashing by trimming off the ends of the cordage, or leave some showing to make untying easy.

Through Joint

1. Another simple bamboo joint is the through-joint. A hole is drilled through an upright pole so that a smaller cross- pole can pass all the way through. Then it is lashed securely, both to tighten the joint and to prevent splitting.

These joints are often used when making bamboo fence panels or rafts by passing the bamboo crossbar through a line of holes made in the bamboo poles.

2. The holes in the upright must be made large enough to let the nodes of the cross-pole to fit through (unless the nodes are sanded down first), so bamboo lashings are needed to secure the joint which will be quite loose. Adding a peg to this joint to pin the poles in place is a good way to prevent the cross-pole from shifting to the left or right.

How to repair split bamboo?

When bamboo poles are cracked, or if they split while drilling a hole, you can fix it with a simple split closing tool.

1. The split-closing tool is made from two levers and a short length of lashing rope. Tie a bowline at each end of the rope.

2. Slip one bowline loop over the end of one lever, then lay the bamboo across the lever. Wrap the rope around the bamboo over the split area (two or three times), and then slip the second bowline loop over the end of the second lever as shown above. The exact length of the rope can be adjusted by re-tying the second bowline loop if needed.

3. Now rotate the second lever around the bamboo pole to tighten up the rope so that the split is squeezed shut.

4. Another length of cordage can be used to keep tension on the levers if you are working alone.

5. Now lashings can be added to the split area to keep the split closed after the tool is removed. Long splits may have to be lashed in several places to close the entire split.

Source: Buckon Beach

Comments

Pat wrote:

I'd like to know what sort of cord is used in the above images.