Bamboo Cables

Marco Polo was the first to reveal the domestic value and importance of bamboo to the Western World trough his historic travels in Asia. Among many other discoveries, he described how the Chinese used and manufactured bamboo cables for towing boats.

In fact, engineers experimenting for the Whangpoo Conservancy Board found out that these twisted and plaited bamboo cables were made with material taken from the outer layer of the bamboo (which was only 1/8 inch or 3 mm thick). These bamboo cables where then used to tow junks up against the current of the rapids In the gorges of the Yangtze River and estimated that the working stress was about 20,000 pounds per square inch, which was of the same order as normally taken by steel wires of the same size.

The breakages were very few with bamboo cables. Moreover, while hempen ropes lose some 25 percent of their strength when wet, the tensile strength of plaited bamboo cables increases about 20 percent when they are fully saturated with water. Bamboo cables were available in lengths up to a quarter mile. As many as 300 men may have been tugging on them in the Yangtze rapids.

Bamboo Suspension Bridges

Bamboo Suspension Bridge - Courtesy: Paul S.

Bamboo cables were the earliest structural element in the history of engineering to be used for suspension bridges, which originated in western China and the Himalayas.

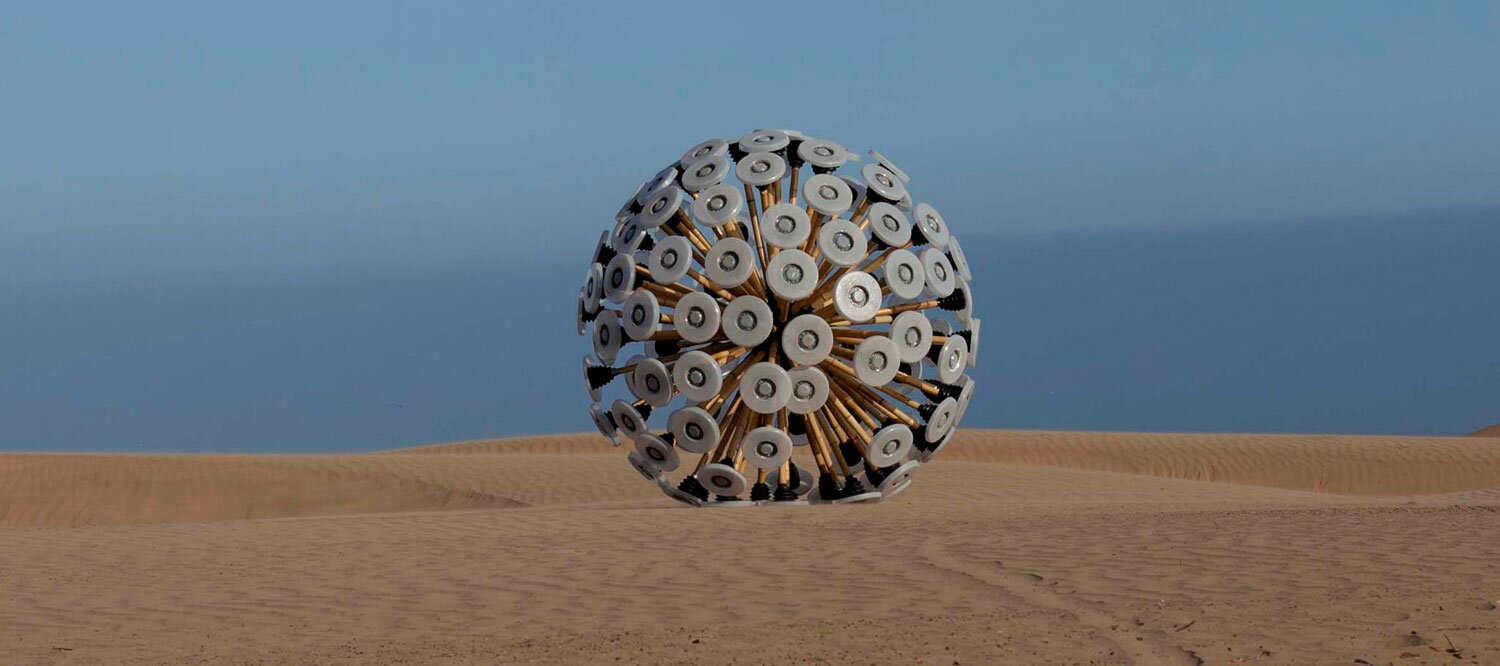

Primitive bridges made of bamboo cables droop across gorges with one end fixed lower than the other. Bamboo tubes greased with yak butter slide down the cables, with a cradle hanging from them in which people and animals side. Of great strength, a bamboo cable of 2 inch diameter could support 4 ton, these ancient bridges spanned distances up to 76 meters without central supports.

Later on, various designs combined whole bamboo culms, woven slats, and cables braided of workable species such as Gigantochloa apus, which was a favorite for bridges in Java.

The Anlan Bridge

The remarkable Anlan bridge on the Min River in China was first constructed around 300 AD. Historians consider this bridge one of the engineering marvels of the ancient world. Until replaced with steel cables in 1975, the suspension cables were made of bamboo.

The Anlan suspension bridge spans the 1,000-foot wide Min River, is 9 feet wide, and was built entirely of bamboo cables resting on seven supports fixed equidistant in the bed of the stream. The floor of the bridge rested across 10 bamboo cables, each 21 inches in circumference, and five similar cables on each side form the rails.

People have walked across the Anlan Bridge for 1,700 years. Courtesy: David Newbegin

The cables were all fastened to huge capstans, embedded in masonry, which were revolved by means of spars to keep the cables taut. The floor of the bridge was made of planking held down by a bamboo cable on either side. Lateral strands of bamboo kept the various cables in place, and wooden pegs driven through poles of hard wood assist in keeping the floor of the bridge in position. Not a single nail or piece of iron was used in the whole structure. Every year the cables supporting the floor were replaced by new ones, they themselves replacing the rails.

The Bamboo cables were made in the same way as those used for towing ships against the current of rivers, but of larger dimensions. Bamboo strips from the inner culm form a core in the center of the rope, and round them was woven a thick plaiting of bamboo strips taken from the outer silica-containing layers. The plaiting was done so that the outer portion griped the core more tightly and increased the tension. Such ropes were generally about 2 inches thick, and three or more twisted together formed one of the bridge cables.

When placed in a testing machine, the straight inner strands broke first, while the plaited material showed very great strength, not rupturing until a stress of 26,000 pounds per square inch was reached, though an ordinary 2 inch hemp rope can carry a stress, of only about 8,000 pounds per square inch. Moreover, the silica-containing outer surface is very resistant to wear, e.g., against rock surfaces, which is naturally important both in towing and bridge cables.

How to Plait or Braid Bamboo Cables?

Bamboo cables are made by first splitting bamboo canes over their entire length into thin strips. Once the strips are obtained, the soft inner layer needs to be removed from the silica-rich outer layer. A Nicaraguan bamboo basket maker demonstrates how to separate the inner from the outer layer in the video below.

Strips from the outer layer of the bamboo culm are than twisting and braided together into ropes as shown in the following illustration:

Courtesy: Oscar Hidalgo Lopez, Manual de construcción con bambu.